94-02 2500 3500 Dodge Ram 4x4, Steering Stabilizer Bar Free Shipping on 2040-parts.com

Milwaukee, Wisconsin, United States

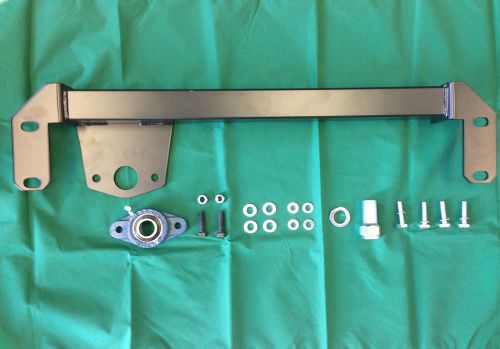

Dodge Ram Steering Gear Box StabilizerFits on: 1994 thru 2002 Dodge Ram, 2500 or 3500 - 4x4, (Gas or Cummins Diesel) 1994 thru 2001 Dodge Ram, 1500 - 4x4

Product Details:

IMPORTANT NOTES: Please read before beginning installation. OEM Manual should be used as a reference. IT IS HIGHLY RECOMMENDED THAT A CERTIFIED MECHANIC PERFORMTHIS INSTALLATION. Read and understand all the instructions before beginning installation. Before installing the Steering Stabilizer bar, inspect all steering components for signs of wear or damage. Replace worn or damaged parts as necessary. This product is NOT designed to be a replacement for a new steering box and/or ball joints and will not fix or replace worn-out steering components. The Steering Stabilizer bar is designed to reduce the stress on the steering box and extend the life of the steering components. Use Loctite® on all bolts associated with this installation. It is the responsibility of the mechanic and customerto wear safety glasses at all times during installation, especially when working with air tools. Before installation begins, drive the vehicle and inspect it to make sure that there are not any uncommon sounds or frame damage. IMPORTANT CUSTOMER INFORMATION: It is the customer’s responsibility to make sure a re-torque is performed on all hardware associated with this suspension system after the first 100 miles and every 1000 miles thereafter and after every off road use. Required Tools: • 15mm&17mm Socket/Wrench • 3/4”, 1-1/4”& 1-15/16” Deep Socket/Wrench • 1/8” Allen Wrench • Torque Wrench (40-180 ft-lb) Torque Settings: Anti-sway bar to frame bolts – 45 ft-lb Sector shaft nut – 180 ft-lb End-link to frame nut – 40 to 60 ft-lb Installation: 1. To begin installation block the rear tires of the vehicle so that the vehicle is stable and can notroll. 2. With a 15mm socket or end wrench, remove the four (4) 10mmmount the anti-sway barmounting bolts.(Two bolts per bracket) NOTE: The anti-sway bar will swing free when the bolts are removed. Allow the bar to rest on the steering linkage, but be sure to support the bar to avoid excessive load on the end links. 3. Remove the sector shaft nut and lock washer using a 1-5/16” socket. Retain the lock washer for re-installation. Take care to ensure no thread damage occurs with the removal of the nut. 4. Apply Loctite and attach the provided sector shaft nut with a 1-1/4” wrench reusing the lock washer. Hand-start the nut to ensure no crossthreading occurs. Torque sector shaft nut to spec. 5. Slide the stabilizer bar into place, so the feet are between the frame and sway bar mounts. Ensure that the large diameter hole on the bearing plate is approximately centered on the sector shaft nut 6. Apply Loctite to the provided 10mmsway bar mounting bolts (x4) and install using a 17mm socket or end wrench.Do 7. Installtwo ½” bolts through the holes in the bearing mounting plate so the threads are hanging through the bracket. 8. Install bearing over the sector shaft nut and bolts until it comes in contact with the support bracket. NOTE:the bearing block may not be flush to the support bracket at this point. Install lock washer and nut using a ¾” socket; snug, do nottighten. 9. Tighten all bolts in the following order: 1. Sway bar mounting bolts-torque to spec. 2. Bearing bolts 3. Bearing set screw 4. End-link bolts

This takes the slop out of your steering

FREE SHIPPING TO LOWER 48 STATES |

Sway Bars for Sale

07 06 05 04 03 02 01 00 99 99 98 97 96 95 94 93 92 91 90 ninja 250 tank bracket(US $12.50)

07 06 05 04 03 02 01 00 99 99 98 97 96 95 94 93 92 91 90 ninja 250 tank bracket(US $12.50) P2m for nissan 240sx offset rack spacer + inner tie rod + pro type outer tie rod(US $500.00)

P2m for nissan 240sx offset rack spacer + inner tie rod + pro type outer tie rod(US $500.00) Sway bar - link kit extra(US $109.46)

Sway bar - link kit extra(US $109.46) Sway bar link (front) - crown# 5174060ac(US $45.42)

Sway bar link (front) - crown# 5174060ac(US $45.42) 2 sway stabilizer bar link links bmw e24 e28 e30 e32 e34 e36 325 525 31351134582(US $27.95)

2 sway stabilizer bar link links bmw e24 e28 e30 e32 e34 e36 325 525 31351134582(US $27.95) Energy suspension 9.5126r sway bar bushing set fits 94-97 accord odyssey(US $26.75)

Energy suspension 9.5126r sway bar bushing set fits 94-97 accord odyssey(US $26.75)

Center stack is new high-stakes battleground; showdown with safety regulators looms

Mon, 05 Sep 2011For auto suppliers and gadget companies eager to get a piece of the auto industry, the hottest chunk of vehicle real estate now is the center stack. That corridor of interior space, running from the driver's right hip up through the center of the cockpit to the bottom of the windshield, has become a California gold rush of opportunity. But it is less so for traditional suppliers of molded plastics, cables, levers, buttons and radios.

Jaguar Land Rover boss dies (2008)

Mon, 21 Apr 2008Geoff Polites, Jaguar Land Rover CEO: 1948-2008 By Gavin Green Motor Industry 21 April 2008 06:53 Geoff Polites, who died yesterday aged 60, will go down as one of the great British car industry bosses. He took over as CEO of Jaguar Land Rover in September 2005, when the Jaguar half of the business was at its lowest ebb. Sales of the lame duck X- and S-types were fast evaporating; Jaguar was consistently failing to hit its financial forecasts; morale was poor.

Scary cars: AutoWeek's trick or treat list

Fri, 30 Oct 2009It wouldn't be Halloween without a little car fun. So we asked a couple of our writers to hand out their picks for "scary" cars. First up: Kevin A.