West System Epoxy Kit, 105 Gal+ 205 Qt Fast Hardener + Pumps - Low Price + F/s on 2040-parts.com

Waretown, New Jersey, United States

|

105 Epoxy Resin: The key component in a wide variety of boatbuilding, restoration, and repair projects 105 Resin is the base material of the WEST SYSTEM family of products, on which all of the WEST SYSTEM compounds are built. The resin is a clear, light amber, low-viscosity liquid epoxy resin. Formulated for use with WEST SYSTEM hardeners, it can be cured in a wide temperature range to form a high-strength solid with excellent moisture resistance. It is designed specifically to wet out and bond with wood fiber, fiberglass, reinforcing fabrics and a variety of metals. An excellent adhesive, 105 will bridge gaps and fill voids when modified with WEST SYSTEM fillers and can be sanded and shaped when cured. With roller applications, it has excellent thin-film characteristics to flow out and self-level without "fisheyeing." The resin cures clear so that you can achieve a natural finish when coating with varnish. It has a relatively high flash point and no strong solvent odor, making it safer to work with than polyesters. · We strongly recommend the use of WEST SYSTEM dispenser pumps. 205 Fast Hardener: 205 Fast Hardener is a medium-viscosity epoxy curing agent. It is used in a majority of situations, at lower temperatures and to produce a rapid cure that develops its physical properties quickly at room temperature. When mixed with the 105 Resin in a five-part resin to one-part hardener ratio, the cured resin/hardener mixture yields a rigid, high-strength, moisture-resistant solid with excellent bonding and coating properties. Not intended for clear coating.

West System 206 Slow Hardener 206 Slow Hardener® is a low-viscosity epoxy curing agent for use when extended working and cure time is needed or to provide adequate working time at higher temperatures. When combined with 105 Resin in a five-part resin to one-part hardener ratio, the cured resin/hardener mixture yields a rigid, high-strength, moisture-resistant solid with excellent bonding and coating properties. Not intended for clear coating. Pot life at 72°F (22°C): 20 to 25 minutes

West System Special Coating Ha This hardener was especially developed for use with WEST SYSTEM Brand 105 Resin in coating applications where an exceptionally clear, moisture-resistant, natural wood finish is desired. Cures to a light amber color, similar to traditional spar varnishes. An ultraviolet inhibiting additive improves the resistance of a WEST SYSTEM 105/207 mixture to sunlight, but the cured epoxy surface will still require the additional protection of a quality UV-filtering varnish. 207 is designed to self level for smooth finishes, and to wet-out and bond fabrics. Although it provides good physical properties for general bonding applications, it is more difficult to thicken and less cost effective for this purpose than 205 or 206 Hardeners. It’s also used for laminating veneers where bleed through at joints may be exposed to sunlight.

|

Paint & Maintenance for Sale

Camco 210 plastic cleaner polish - 14oz spray - case of 12 -40934case(US $156.29)

Camco 210 plastic cleaner polish - 14oz spray - case of 12 -40934case(US $156.29) Shurhold 6- 1/2;" soft brush f/dual action polisher -3207(US $29.28)

Shurhold 6- 1/2;" soft brush f/dual action polisher -3207(US $29.28) Oem evinrude johnson brp freshwater flushing kit - 435299(US $33.97)

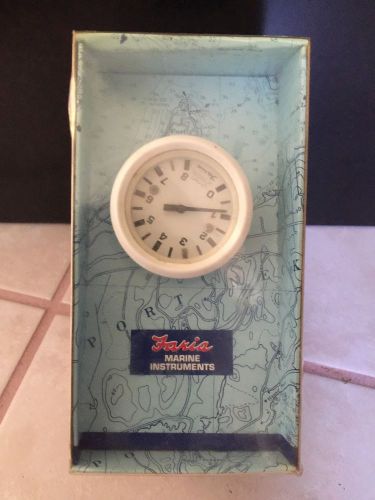

Oem evinrude johnson brp freshwater flushing kit - 435299(US $33.97) Faria tach 12 pole pwc 2 1/16" limited space dash 8k white face & bezel(US $49.95)

Faria tach 12 pole pwc 2 1/16" limited space dash 8k white face & bezel(US $49.95) 3m 7093 particulate filter p100 (12/bx) 5000 6000 7000 series bayonet style(US $50.00)

3m 7093 particulate filter p100 (12/bx) 5000 6000 7000 series bayonet style(US $50.00) Yamaha yamalube 4-stroke outboard 5w-30 full synthetic 4m fc-w oil one quart(US $12.13)

Yamaha yamalube 4-stroke outboard 5w-30 full synthetic 4m fc-w oil one quart(US $12.13)

'Super salesman' calls time on 100,000-sale career

Thu, 06 Mar 2014A SO-CALLED ‘super salesman’ is calling time on his career after notching up an incredible 100,000 car sales over half a century. Ken Searle, who works for Benfield Motor Group in the North East, started with British Leyland before moving to a new team selling Datsun cars when they first arrived in Britain. A proud Ken said: “I’ve loved every minute of my career and I wouldn’t have changed a thing.

Wannabe racers invited to test their mettle

Mon, 07 Apr 2014THE AMAZING scenes at the Bahrain Grand Prix have left an unfamiliar warm glow surrounding the pinnacle of motorsport, but at grass roots level would-be racers are being invited to show their potential. The Lets Race 2 Reality scheme, open for entries until the end of the month, will reward the best new racing driver in the country with an incredible Formula 3 race experience. The winner will receive a day’s testing in a Carlin Formula 3 car, complete with a dedicated team of mechanics, data engineer and race engineer.

Hennessey shows off breakneck speed of Venom GT

Wed, 14 Sep 2011The boys at Hennessey Performance in Houston have been showing off their Venom GT supercar for almost a year now. We know it is fast. But in case we weren't convinced, they sent us this video of the speedometer going from 70 mph to 215 mph in about 10 seconds, complete with sound.